Liquid Helium Transfer Lines

Liquid helium transfer lines are used to transfer liquid helium from a storage dewar to the magnet system dewar.

These lines are usually constructed of all-welded stainless steel. To aid in handling the line, the center section is vacuum-jacketed flexible piping. This piping is connected on either end to smaller diameter non-flexible vacuum-jacketed tubing. These smaller diameter tubes are inserted into the storage dewar and the magnet dewar.

Although LHe transfer lines are rugged and can give years of service, they must be handled correctly in order to maximize their lifetime.

It is very important that the non-flexible tubes are inserted into the storage and magnet dewars in a straight up and down motion. Bending the non-flexible tubing while it is supercooled will apply too much stress to the welds and will eventually cause failure.

Transferring liquid helium is a minimum two-person operation. One person needs to guide the tube into the storage dewar and the other person needs to guide the tube into the magnet dewar. Each person should be positioned so they may grasp the large curved tubing between the flexible and small outside diameter tubing. Additional personnel may be positioned at the tube ends to help guide the tube into the dewars.

Stable platforms should be provided to stand on if the storage or magnet dewar is too tall for personnel to refill while standing on the floor.

Do not allow the weight of the transfer line to be supported by the small outside diameter tubing!

Using proper equipment to protect the operators from frostbite, have the personnel on the storage dewar leg carefully guide the tube into the storage dewar until it is slightly submerged in liquid helium.

Allow the transfer tube to cool until a plume is noticed on the magnet dewar side leg of the transfer tube. The personnel operating the magnet dewar leg should then carefully guide the tube into place. It is very important that all personnel handle the tube assembly by the large curved tubing and the flexible tubing – not the small outside diameter tubing!

After refilling the magnet dewar, carefully remove the transfer tube by pulling straight up using the large curved tubing. Use extreme care not to bend the small outside diameter tubing of the assembly.

For further safety tips, please contact the factory.

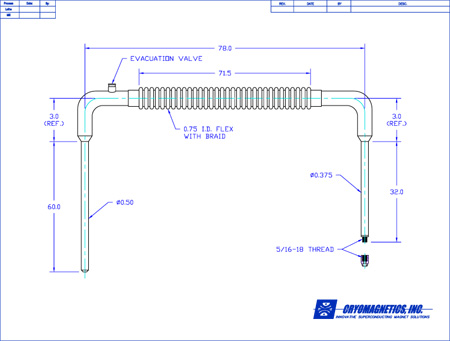

Superinsulated, stainless steel construction with 71.5″ flexible section. Rugged, yet easy to handle.

Superinsulated, stainless steel construction with 71.5″ flexible section. Rugged, yet easy to handle.

Industry standard 0.5″ O.D. storage dewar leg, 60″ in length. 0.375″ O.D. stinger, 32″ in length.

Custom lengths are available per quotation.